Too much and not enough inventory at the same time destroys your plant and business performance. Here’s how to stop the Stock Shock effect:

Do you evaluate inventory levels by “months” or “days” of remaining stock?

In this article, we’ll discuss why that approach is insufficient, how it causes inventory imbalances that hurt your bottom line, and how a Demand-Driven Replenishment approach (explained below) can transform your results.

What is inventory imbalance?

An inventory imbalance is just what it sounds like: when you have too much or too little of a SKU compared to the target for the stocking item.

The bigger, trickier questions are why do inventory imbalances occur, and what can you do about them?

Forecasting difficulties (see more below) are the root of the problem, along with disagreements about ideal inventory levels between operations and finance.

Finance wants to keep inventory down to conserve cash. Operations typically aims for higher levels to accommodate consumption and supply factors.

(The reality is that finance is not opposed to inventory – but they want to see the business improve return on investment and cash flow KPIs.)

How inventory imbalance affects KPIs

These converging factors typically result in both overstock and understock SKUs that create a stock shock effect that reverberates throughout the plant and negatively impacts these key performance indicators (KPIs):

- Cash flow dries up.

- Throughput drops.

- Sales slow down.

- Expediting and overtime increase.

- Your bottom line suffers.

Inventory imbalance is like a wrecking ball on these key KPIs that drive plant and business performance.

But what about your MRP?

Now for the elephant in the room: Shouldn’t your MRP be able to solve this problem?

The truth is no MRP can do it alone. Here’s why:

Conventional MRP algorithms depend on accurate forecasts of future orders.

And accurate forecasting is impossible because:

- Customer orders change *all the time*, which throws even the best forecasts out the window.

- Plant performance varies.

- Suppliers are unreliable.

To compensate you add safety stock, you use a min/max approach, you rely on intuition. But it’s still not enough.

Break the cycle with Demand-Driven Replenishment

A Demand-Driven Replenishment (DDR) approach can help you break this stock whiplash cycle.

DDR is a Theory of Constraints (TOC) approach to supply chain management. It accounts for the realities of customer demand variability, and supplier and plant performance inconsistencies for an effective, efficient response in real-time.

DDR requires consistently maintaining small inventory levels, pegged to correct targets.

Ideal inventory targets are designed and managed to accomplish the twin objectives of minimizing operating costs and maximizing stock availability.

Doing so provides the stability your manufacturing floor and overall supply chain requires to deliver peak results.

How to determine ideal SKU-level inventory targets

To determine the ideal maximum SKU-level inventory targets, you need visibility to:

- Item transaction frequency

- Related lead times

- Consumption level fluctuations, and more

This information is used to create properly located inventory buffers that absorb the impact of supply chain variability (customer, supplier and the plant).

These buffers are a combination of:

– in-stock inventory (similar to kanbans), and

– inventory on the way (from your suppliers or in the plant)

If all that sounds complicated and time-consuming, it doesn’t have to be.

Roadrunner’s inventory management algorithm makes it easy

Montera’s Roadrunner Rx Inventory Management Service uses a proprietary algorithm based on the principles of DDR to calculate ideal target inventory buffers.

A real time feedback loop monitors demand and supply versus actual on-hand inventory levels.

Fluctuations in demand and supply are absorbed by the buffer wall preventing stockouts and as inventory consumption occurs, it reorders what’s used.

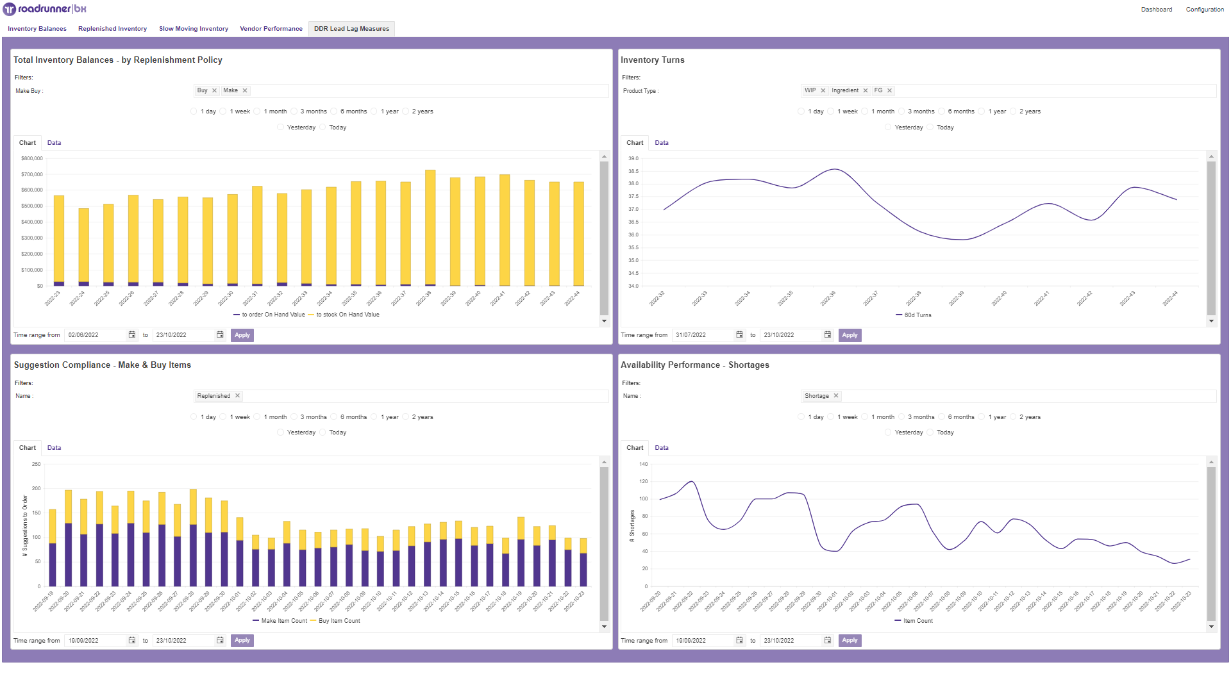

The Roadrunner inventory scorecard provides real time visibility to:

- inventory performance

- inventory levels

- returns

- shortages, and more.

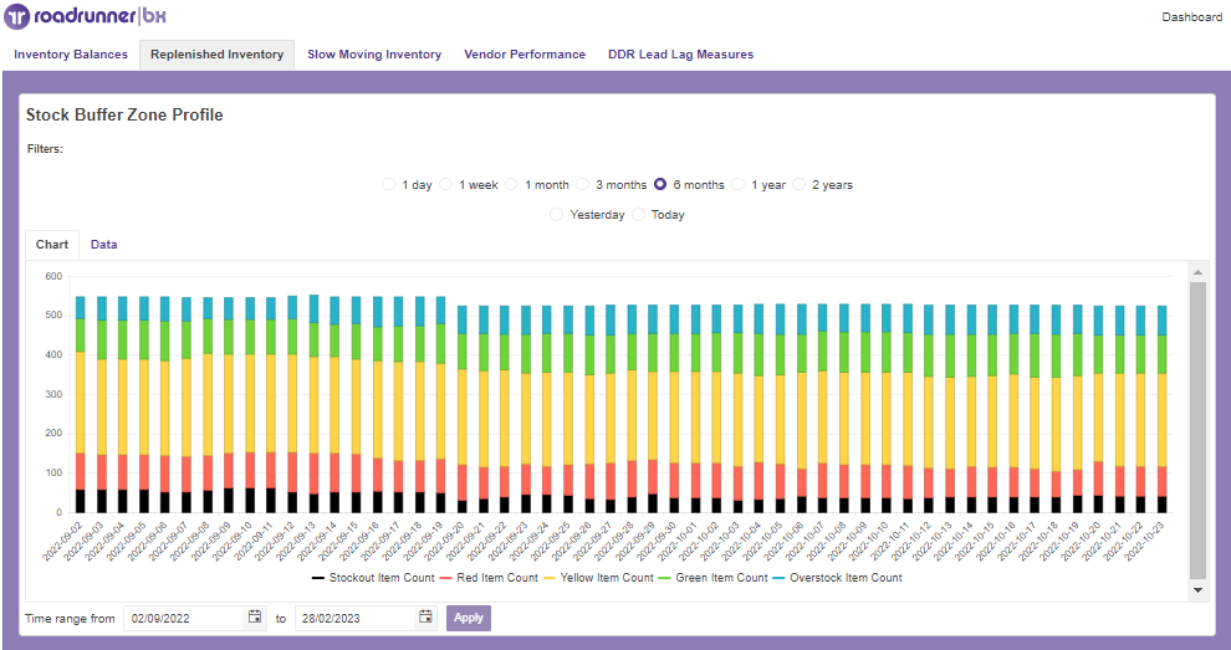

Our stock buffer zone profile provides ongoing trend evaluation of inventory position against buffer targets that affect working capital and revenue. You can monitor process improvements and their impact on business performance.

The best part is that we send regular order requirements directly to your ERP, so you know exactly what to buy and ship.

It ensures you ALWAYS have the correct stock on hand to maximize cash flow AND fulfill orders on time.

It enables our clients to routinely cut inventory by 25% to 40%.

And it works with all MRP/ERPs.

Is inventory imbalance hurting your results? Our no obligation inventory imbalance report will show you. See what’s involved in getting your report, and what data is required.

Get your FREE inventory imbalance report

Scores of manufacturers supplying complex multi-part subcomponents to global OEMs rely on Roadrunner Rx to balance inventory levels and improve supply chain efficiencies.

Learn more about our Roadrunner Rx Inventory Management Service and start with a FREE Roadrunner Rx inventory imbalance report: