MANAGED SERVICE:

Right-size your inventory with Roadrunner Rx

Real-time optimization to cut costs, release cash and drive revenue, fully managed for you.

Start with a FREE Roadrunner Rx inventory imbalance report:

Yes, I want my report!Goodbye inventory imbalance, hello full throttle performance

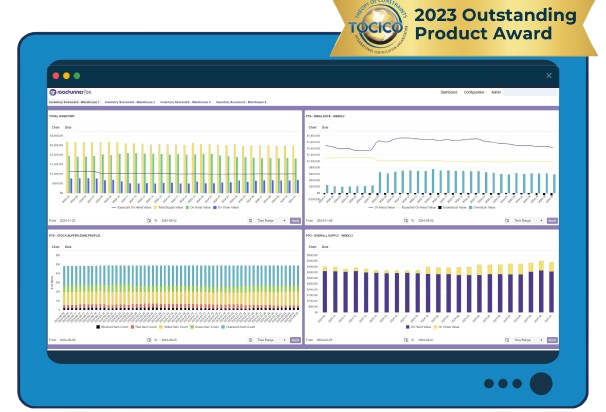

Roadrunner Rx is the only inventory management service that analyzes, monitors and optimizes your inventory in real time.

You get “what to buy” recommendations based on customer demand, supplier reliability, plant performance and other factors.

Slash overstock and prevent stockouts to unlock cash, boost productivity and accelerate throughput.

The best part? We take care of all for you. You take credit for the results.

“Roadrunner Rx Inventory Management Service is steadily reducing our on-hand inventory:

the most recent service centre we added had a 28% reduction in the first three months.”

Director of Operations, North American manufacturer

We make it easy to get results like these:

Reduce Inventory (and

release cash) by at least

25%

Increase product

availability to

98%

Reduce lead

times by

50%

Increase delivery

performance to

99%

“Roadrunner links beautifully with an ERP system. It will help you optimize working capital and discover hidden production capacities. We grew an injection moulding company from 11 million EUR/year in sales to nearly 50 million EUR/year, using Theory of Constraints and Montera software solutions. Just bloody do it!”

Mark Stemberger, Turnaround and Restructuring Specialist

Our experts manage it all for you

- Manage Component / Raw Materials Buffer Inventories

- Design and re-size levels, locations & optimize turns

- Help with new materials replenishment introductions

- Communicate Daily Order Requirements – What to Buy / Ship

- Monitor Supply Chain Pipeline Status (ensure right supply)

- Design and Maintain Inventory Performance Scorecard

- Evaluate Vendors and Purchasing Team’s Performance

- Generate Slow and Non-moving Inventory Reports

- Create Purchase Order Expedite List

CASE STUDY

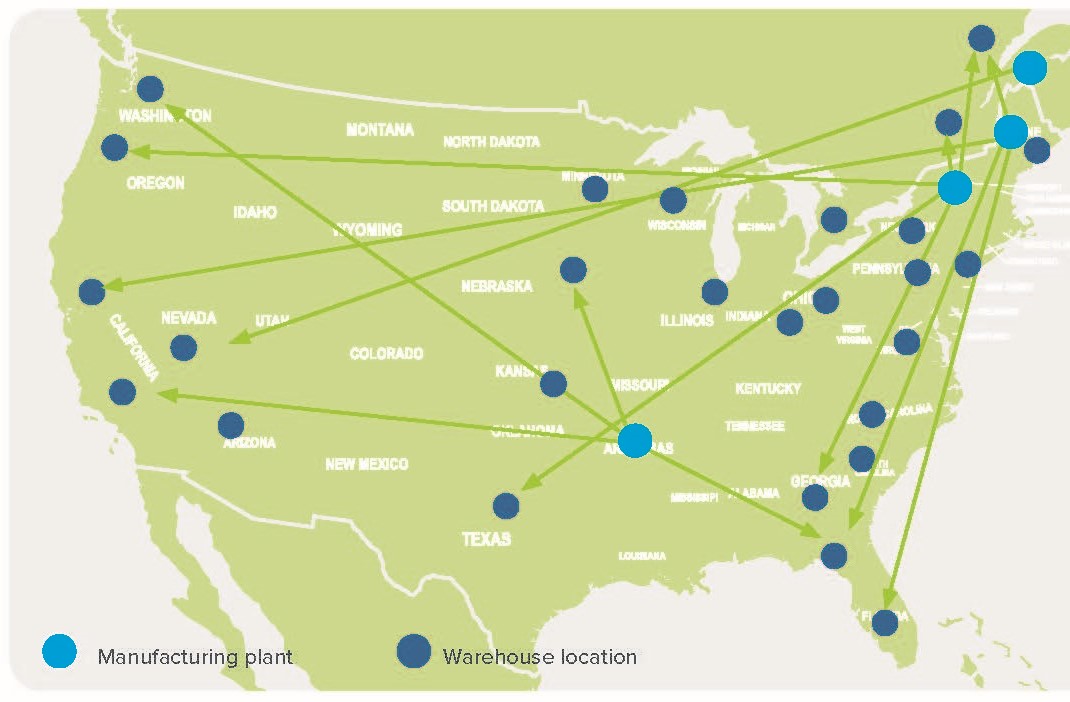

Ideal for manufacturers supplying global OEMS

Product availability up.

Inventory levels and transport costs down.

This North American manufacturer makes approximately 3,000 individual SKUs —for multiple customers, spread out across North America, in a make-to- order environment (4 manufacturing plants and about 30 warehouses across North America.)

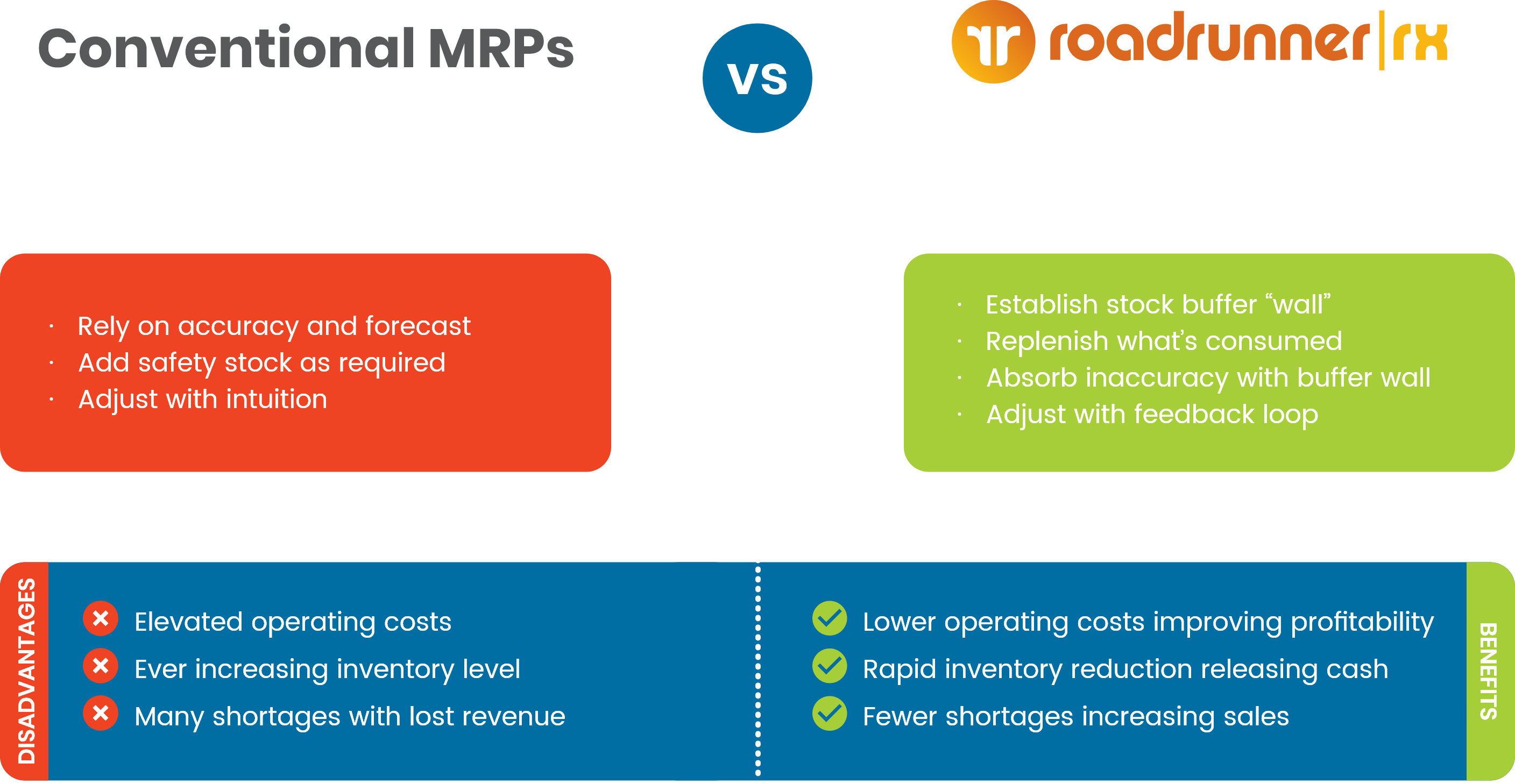

Operating on a 24/7 basis with a new ERP/MRP system, the challenge for this company was to find a way to maximize customer service levels and increase sales while minimizing transportation and inventory costs.

Works with all popular ERPs

5-steps to better plant performance

Send us your inputs. We’ll take care of the rest.

Phase 1:

Data analysis

and modelling

• Define, generate and verify integrity of inventory data set

• Analyze data, define buffering requirements and calculate inventory buffer sizes

Phase 2:

Process design and

software set-up

• Generate feedback and finalize inventory design (SKUs, locations, sizing)

• Set-up / Update roadrunner software and scorecard hosting services

Phase 3:

Replenishment

and Improvements

• Initiate inventory replenishment services including daily communication of What to Make and What to Buy quantities

• Define on-going communication mechanism and stakeholders involved

Phase 4:

Process feedback

and optimization

• Set-up Scorecard, KPIs and process monitoring frequency

• Evaluate impact on inventory turns, inventory imbalance and product availability

Phase 5:

Ongoing

service

• Initiate ongoing service driving inventory performance improvements

Pay by the month.

No entry fee. No exit fee.

Reports include:

- Daily order requirements (What-to-Buy)

- Supply chain pipeline status (right supplies delivered at the right time)

- Inventory Performance Scorecard

- Vendors and purchasing team’s performance

- Slow and non-moving inventory reports

- Purchase order expedite lists

Get started today

Get your FREE inventory imbalance report

Scores of manufacturers supplying complex multi-part subcomponents to global OEMs rely on Roadrunner Rx to balance inventory levels and improve supply chain efficiencies.