Throughput #13

Standing still is never an option in manufacturing.

Global competition, volatile supply chains, rising costs, and customer demands mean operations leaders are under constant pressure to improve.

But the natural question is: how?

- Do you invest in new technology (ERP systems, IoT monitoring, automation)?

- Or do you invest in skill development (Lean/Theory of Constraints/Six Sigma training)?

Both routes can deliver results, but both come with trade-offs.

- New technology can be costly and slow to integrate.

- Training workers is time-consuming and hard to scale.

Most manufacturers end up stuck, making incremental improvements instead of real breakthroughs.

But what if you didn’t have to choose?

A third way: technology + expertise as a service

Instead of buying new tech or building skills in-house, manufacturers can outsource both the tools and the know-how.

That’s exactly what Stalmax, a global auto fastener manufacturer, decided to do to handle inventory management.

- Founded in 1982, Stalmax has consistently invested in growth: new plants, upgraded machinery, and automation software.

- A few years ago, they adopted our Flow Management System with four Roadrunner software modules to embed Theory of Constraints (TOC) and Lean Thinking methods into their operations and supply chain management.

- Results came quickly – revenue has doubled and net profit has increased even faster.

- Impressed with the quick traction, Stalmax team members attended our Goal Simulation Workshop and realized they could further capitalize on our expertise specifically around inventory management.

- In January 2025, Stalmax signed on for our full Roadrunner Rx Inventory Management Service (IMS).

- Why? Because it allows them to tap our deep TOC expertise and Roadrunner software knowledge, day in and day out, for recommendations about what to buy and what to make, continually adjusting to customer demand in real-time.

The outcome?

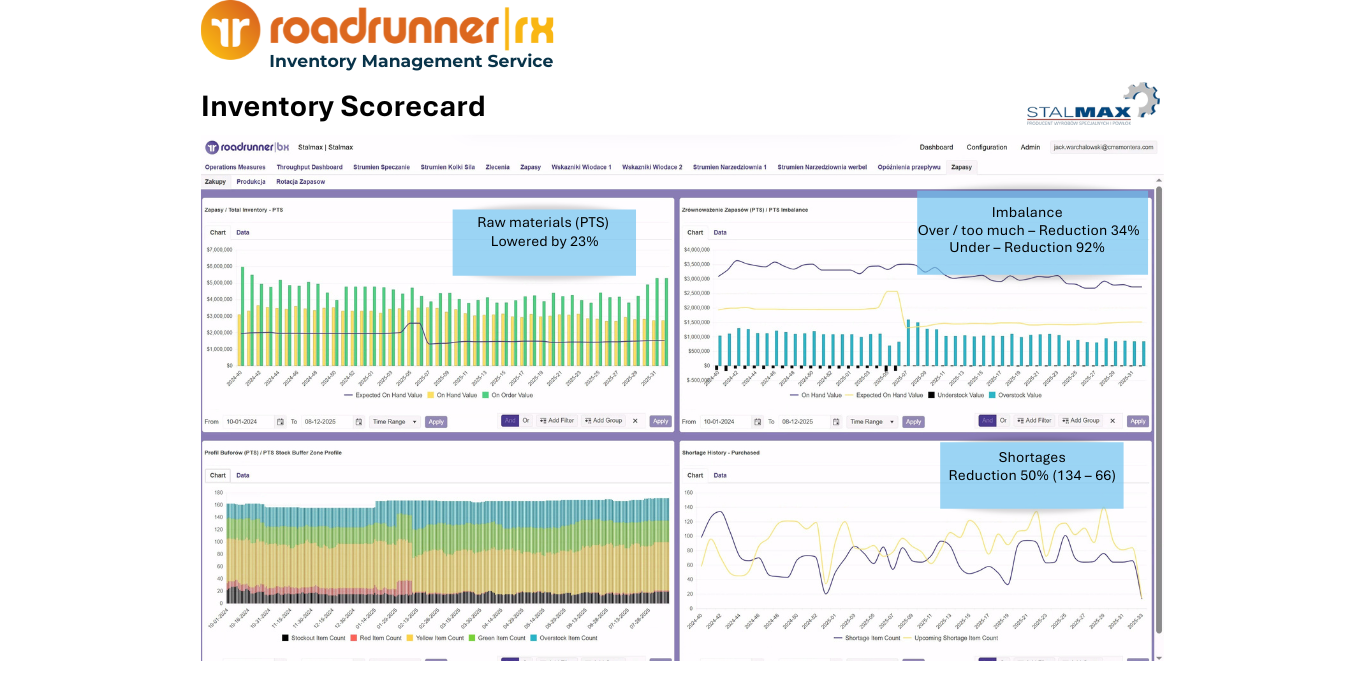

- Stalmax reduced their inventory investment by 25% by increasing inventory turns for all purchased and manufactured items

- Finished Goods Inventory Turns (MTS) increased by 30%

- Raw Materials Inventory Turns (PTS) increased by 20%

Roadrunner Rx IMS Results (Stalmax, Jan-Aug 2025):

Instead of choosing between new tech or investing in new skills, Stalmax chose both — achieving leaner, more resilient inventory management without the burden of massive tech spend or retraining.

I didn’t think we could improve so much so quickly. Thank you, Montera!”

Robert Jez, CEO

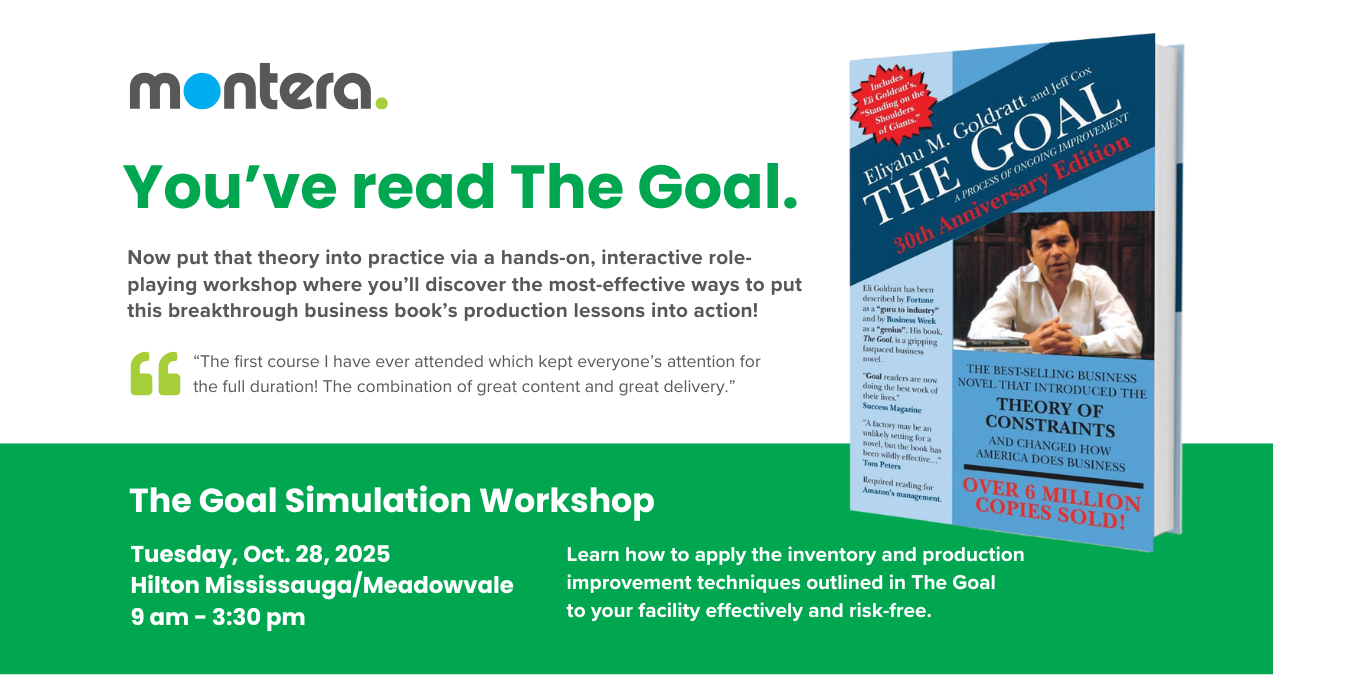

The Goal Simulation Workshop: Mississauga, Ont., Oct. 28

We have two seats left for our Goal Simulation Workshop Oct. 28 (9 am – 3:30 pm) at the Hilton Mississauga/Meadowvale in Ontario, Canada.

Contact me or email [email protected] to book your spot today.

Or ask us about booking a customized Goal Simulation Workshop for your team.

— Jack Warchalowski, Montera CEO

[email protected]

Connect with me on LinkedIn