Throughput #15

It’s been a tough year for manufacturers everywhere.

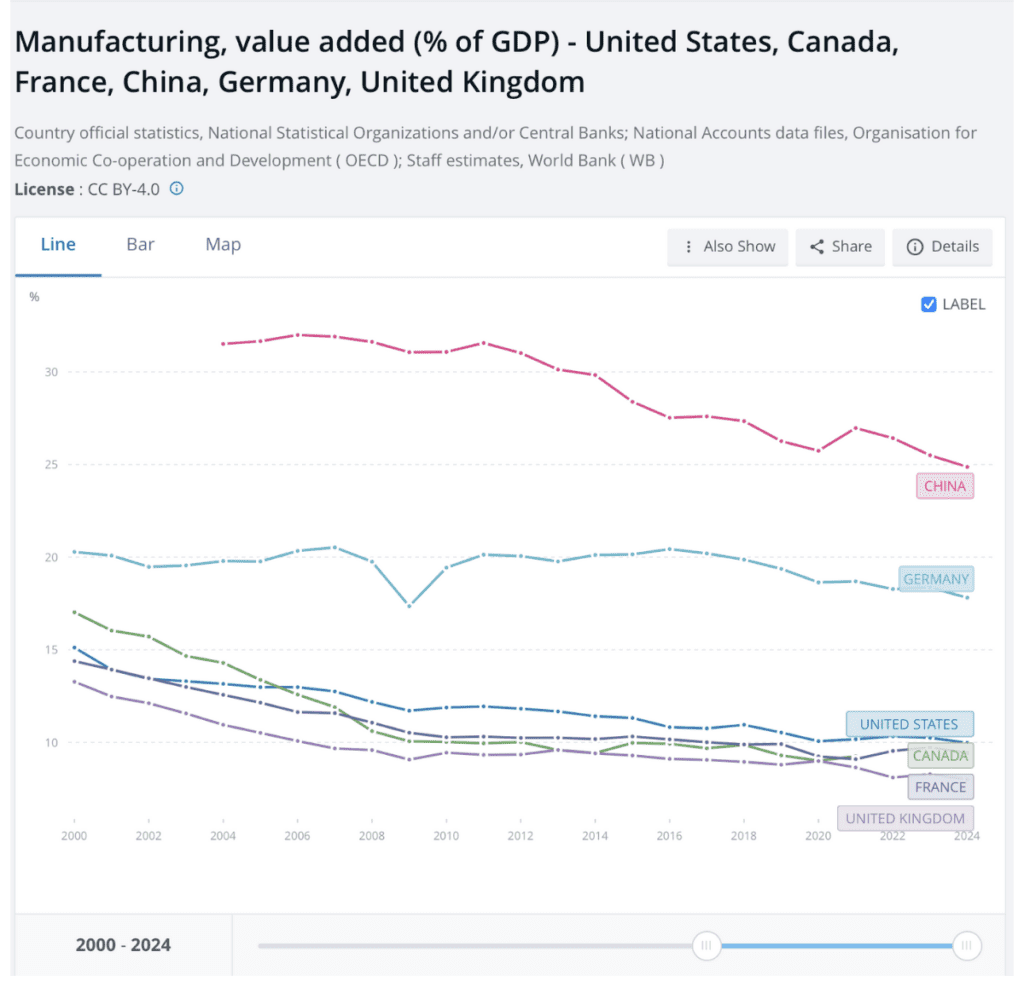

In the U.S., labour productivity is stagnating, and manufacturing value as a percentage of GDP has decreased from 15% to 10% from 2000 to 2024 (as it has for other countries including Canada, France, China, Germany and the U.K).:

The prevailing wisdom is that this decline is due to:

- increased productivity from automation and technology

- a shift in consumer demand towards services and away from manufactured goods

- the integration of China into global manufacturing supply chains after 2001

Given this backdrop, what can be done to make manufacturing strong again?

Some believe that increased tariffs are the answer.

Other pundits routinely call for a multifaceted approach that includes:

- Investment in advanced technologies to increase productivity

- Workflow optimization – implement Lean, maximize efficiency, reduce waste, standardize processes, focus on quality

- Develop a skilled workforce through targeted training and learning programs – foster a culture of continuous improvement and innovation

- Strengthen supply chains

- Enhance government policy and support

We can’t argue with any of the above 5 suggestions. They are all good things to do and have been talked about for years. In fact, we don’t know a manufacturer who ISN’T trying to implement at least some of these things.

But none of these approaches address the fundamental problem why:

Manufacturers are misusing their capacity.

- They produce the wrong thing at the wrong time

- They produce what they don’t need

- They don’t produce anything – resulting in downtime

- They produce poor quality products

As a result, output declines, labor productivity stagnates and costs increase.

So, why does this happen?

Our experience has shown the root cause is a combination of two key reasons:

Reason #1:

Local efficiency measures are driving most work centers and departments

Manufacturers who are focused on local efficiency measures too often:

- Release orders too early to keep resources busy

- Pull orders ahead to create bigger batch sizes

- Make to forecast to keep resources busy

- Buy more than needed to lower unit costs and reduce freight

Even if you agree, you can’t just abolish local efficiency measures – you need a substitute.

Instead, we successfully replace them with Schedule Adherence: a measure of what was supposed to be produced during a shift versus what was actually produced.

Schedule Adherence is measured only at the drum(s) – the constraint or bottleneck.

This maximizes plant flow and resulting throughput. Everyone else needs to do whatever is needed to enable the drum to complete the schedule. If all you do is focus manufacturing on the achievement of Schedule Adherence, you will already improve.

Reason #2:

Not enough of the right raw materials available at the right time.

Many manufacturers, in order to have the right materials available at the right time, rely on a forecast, use min/maxes, add safety stocks, and then are forced to use their intuition for final adjustments – since the above methods are far from perfect.

We break this cycle with Demand-Driven Replenishment (DDR), which requires:

The DDR approach ensures that manufacturers have enough of the right materials at the right time. It also decreases inventory levels and improves cash flow.

By switching to utilizing a Schedule Adherence KPI and Demand-Driven Replenishment approach, manufacturers can maximize their productivity and Make Manufacturing Strong Again.

If you want to improve productivity and profitability at your plant in 2026, email me and let’s talk.

— Jack Warchalowski, Montera CEO

[email protected]

Connect with me on LinkedIn