Montera CEO Jack Warchalowski and Executive VP Duncan Patrick share their expertise on Critical Chain Project Management (CCPM) applications at the Critical Chain 2024 conference April 17-18.

LEVERAGING CCPM FOR NEW PRODUCT LAUNCH SUCCESS

Their presentation How CCPM Helps Manufacturers Successfully Launch New Products and Increase Business Profitability explains how applying CCPM to new product development and product launch processes fits with the overall improvement strategy of a manufacturing business.

Implementing CCPM principles at the outset of a project can dramatically cut lead time, which increases the capacity of a manufacturing organization.

“If your team takes six months instead of a year to design and build a prototype, you have actually doubled your capacity, which pays especially big dividends in high-volume manufacturing.”

— Jack Warchalowski, Montera CEO

STALMAX CASE STUDY

The presentation describes how Stalmax, a high-volume manufacturer of fasteners for the auto industry, is successfully leveraging CCPM and Roadrunner Px project management software for their Advanced Product Quality Planning (APQP) and other development processes to increase the profitability of their entire operation.

LIVE Q&A

A live Q&A session with Jack and Duncan will follow the online presentation.

Critical Chain Project Management at scale

Learn more about CCPM methodology at the core of Montera’s Roadrunner Px project management software:

Learn more about our Roadrunner ERP Expansion Pack software for project management, inventory management, production management and business intelligence.

Follow Montera on LinkedIn for conference updates, and more operations and supply chain best practices and insights.

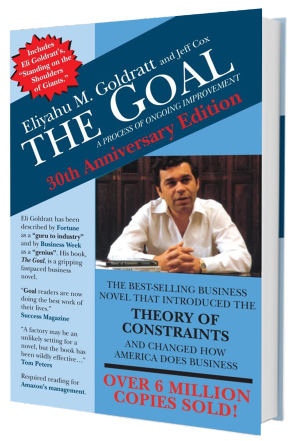

Are you a fan of The Goal?

Put theory into practice with our Goal Workshop for your team.