Harold Karp is a serial CEO who started working with Montera and Theory of Constraints (TOC) in 2008.

He has a remarkable record of producing sustained revenue and EBITDA growth by growing, restructuring and integrating a series of acquisitions and running private equity portfolio companies.

Harold’s extensive experience leading organizations over many years includes about 50 different factories. Many were initially troubled businesses that required an overhaul of their systems and processes.

He described his Theory of Constraints journey in a presentation with Jack Warchalowski, President and CEO of Montera, at the 2018 TOCICO International Conference in Las Vegas, Nevada. In this post, we recap the insights that Harold and Jack shared at the conference.

TOC for ‘large-step improvements’

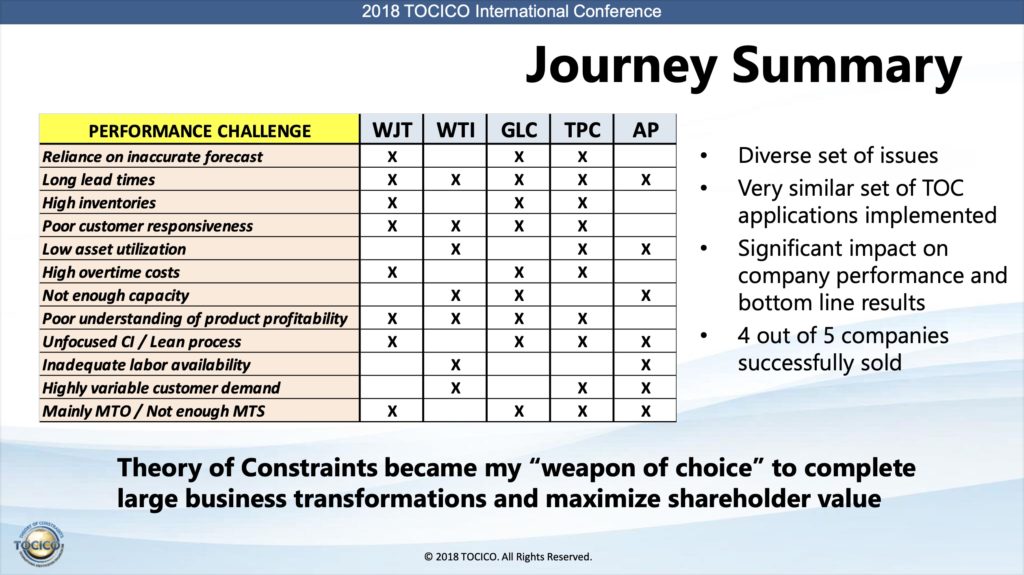

At the TOCICO conference Harold explained why Theory of Constraints became his “weapon of choice” to complete large business transformations and maximize shareholder value at five companies:

- Wolverine Tube, Inc.

- Wolverine Joining Technologies

- Great lakes Copper

- Tecumseh Products

- Applied Process Inc.

In working with Montera, “I was able to gain an understanding of TOC and its impact on the business functions within the manufacturing operation” to get “large-step’ improvements,” Harold said.

Wolverine Tube, Inc.

Harold served as president and COO of Wolverine Tube, Inc. from 2007-2014. The company comprised 3 divisions: Wolverine Joining Technologies, Wolverine Tube Inc. and Great Lakes Copper.

Wolverine Joining Technologies

During Harold’s tenure, Wolverine Joining Technologies (WJT), located in Warwick, Rhode Island, comprised an 82,000 sq. ft. brazing alloy facility with approximately 150 employees.

The fully integrated alloy mill encompassed melting / casting; extrusion hot metal working; wire / rod drawing; strip rolling, slitting, bonding; ring forming and stamping; flux formulation and coating; braze assembly manufacturing; and a metallurgical laboratory.

Performance challenges included:

- Finished and Work-in-Process inventory was too high, and not right (their primary raw material was silver, worth $30/oz in 2012)

- Very long and highly variable customer lead times

- Lower than required on-time delivery to Customer Request Date

- Weak understanding of Product Profitability

- Continuous Improvement project prioritization didn’t result in significant plant performance improvements

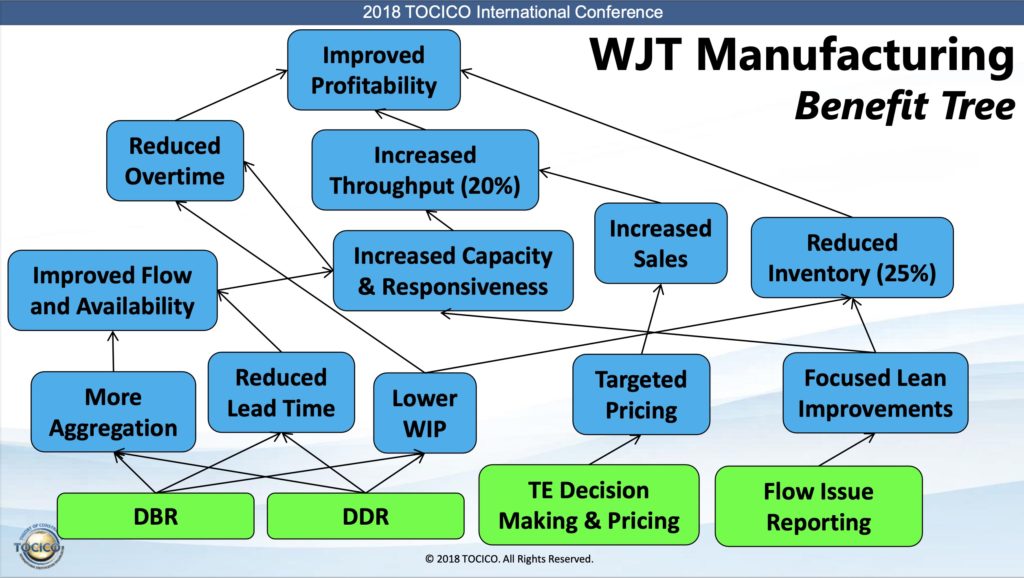

TOC implementation included Drum-Buffer-Rope and Demand-Driven Replenishment principles, as well as Throughput Economics (TE) decision-making and pricing, plus Flow issue reporting.

Results:

As a result of the TOC implementation program, WJT experienced the following outcomes:

- A significant inventory reduction, including WIP

- Excellent visibility of shop floor priorities using Montera’s Roadrunner software

- The TOC implementation increased the sale price of the company

- The company was sold by the time the implementation was complete

Wolverine Tube Inc. Manufacturing

This facility in Shawnee, Oklahoma, built in 1974, was a 325,000 square feet plant that employed 530 workers.

Performance challenges at the time included:

- High working capital investment

- Too long customer lead times

- Poor customer service / responsiveness

- Not enough plant capacity – seasonal

- Too much Work in Process inventory

- Insufficient Overall Equipment Effectiveness

- Poor understanding of Product Profitability and plant Continuous Improvement requirements

The TOC implementation:

- Business Performance Review

- Designed and implemented Drum-Buffer-Rope process for the plant

- 48 drums in technical side of the plant

- Demand-Driven Replenishment for all Make-to-Stock finished goods

- Throughput Economics-based decision making process

- Stream profitability – industrial vs. technical

- Designed Flow Issue Reporting-based Continuous Improvement process

- Supported by Montera’s RoadRunner software

Results:

- Significant Throughput Increase

- Overall Throughput/Operating Expenses (T/OE productivity) increase – also used to understand stream (technical vs industrial) profitability

- On-time delivery improvement

- Company split into two businesses and was successfully sold

Great Lakes Copper

Great Lakes Copper is located in London, Ontario, Canada along the Highway 401 corridor for easy access to the Great Lakes region.

In 2009, Great Lakes Copper was a leading manufacturer of polyethylene coated copper tubing for natural gas, liquefied petroleum gas, fuel oil, potable water and various industrial applications. It was a world Class producer of Line set Coils for the residential central air conditioning market.

Performance Challenges (2009):

- Excessively long lead times

- Very high inventory levels

- Insufficient customer service performance

- High overtime costs

- Lean improvements throughout but not very focused

- Product costing / profitability understanding based on standard costing approach

- Mainly Make-to-Order environment – highly variable customer demand.

TOC Implementation:

- Conducted business performance review in early 2009

- Designed and implemented Drum-Buffer-Rope to manage the plant

- Deployed Demand-Driven Replenishment for all Make-to-Stock products

- Implemented Throughput Economics-based decision making process – new approach to pricing

- Designed Flow Issue Reporting-based Continuous Improvement processInstalled Roadrunner Manufacturing (Mx) and Business Performance Intelligence (Bx) software modules

Results:

- Implemented Process Of Ongoing Improvement (POOGI)

- The Vaughn work centre became a focus for the plant

- Drum Performance screen provided on-going feedback (50% increase)

- Company was sold at a significant premium

Tecumseh Product Company

Tecumseh manufactures compressors in the U.S., Brazil, France and India and operates several assembly facilities worldwide. Founded in 1934, it sells compressors and condensing units under several brand names globally.

Harold served as President & Chief Executive Officer and Board Director. He recalls Tecumseh as one of the toughest companies he took on.

Performance issues (2014):

- Highly reliant on an inaccurate forecast to drive purchasing and planning decisions resulting in: parts shortages, production schedule changes, expediting, higher freight costs, increased over time and longer lead times

- High and variable inventory levels

- Continuous improvement, engineering and maintenance projects prioritized according to cost reduction opportunities, not flow.

TOC Implementation (2014-16):

- Conducted two business performance reviews

- TOC Implemented in the US, Mexico and Brazilian facilities

- Designed and implemented Drum-Buffer-Rope in all plants

- Deployed Demand-Driven Replenishment for all Make-to-Stock finished goods, Raw Materials and Sub-Assemblies

- Implemented Throughput Economics-based decision making process to enable Throughput Economics (TE) based pricing (in the U.S.)

- Enabled Flow Issue Reporting-based Continuous Improvement process

- Installed Roadrunner software to support implementations – including the latest Pricing Evaluation Module (PEM)

- Tecumseh, a publicly traded company, was taken private in the middle of the implementation and sold to a private equity firm at a premium

Results:

- Brazil: Inventory Days on Hand (IDOH) dropped by approx. 28% (no more obsolete inventory)

- Tupelo, MS – 12% inventory reduction (6 month after implementation – target 30%) – On-Time Delivery increase to 95% at the same time

- T/OE productivity – very stable despite significant market challenges

Applied Process, Inc.

Harold was CEO of Applied Process from 2016 to 2020.

Applied Process is the world-wide leader in austempering (salt quench) heat treatment technology for ferrous materials. Its foundry and heat treat metallurgical bench strength are unmatched in the industry.

In 2018, the company had a dedicated research and development center, metallurgists and materials engineers. The plants are state-of-the-science, clean, safe, efficient (ISO 9001-2008 certified.)

Performance Challenges at the time:

- Effective utilization of key pieces of equipment was too low

- Inconsistent operational performance between two plants

- Long lead times in busy season

- No Finished Goods inventory to protect plants from customer order variability

- Plant labor availability

- Continuous improvement process based on perceived cost savings instead of flow improvements

TOC Implementation:

- Conducted business performance review

- Designed and implemented Drum-Buffer-Rope in two plants

- Implemented Demand Driven Replenishment (brand new for AP) for all possible Make-to-Stock products

- Implemented Throughput Economics-based decision making process

- Enabled Flow Issue Reporting-based Continuous Improvement process with new Hours Lost Measures

- Installed Roadrunner software to support and drive all implementations – included highly detail scheduling algorithms and ‘coupled drums’

Results:

- Average monthly year-to-year shipments increased by 9.4% before the end of the implementation: 6% over the first six months; 13.2% over the second six months for a 15% increase in EBITDA)

- Livonia, MI operation shipped 29% more $T (Throughput) in the second half of the year (during implementation)

- T/OE productivity – increased significantly

Summary

These companies all faced a diverse set of issues and challenges. A similar set of TOC applications were implemented in each case that resulted in significant improvements to company performance and bottom line results. Four of the five companies were successfully sold.

Theory of Constraints and Roadrunner software together significantly increase velocity and flow through your business,” Harold observed. “The solutions are not always simple … people have to get into the details and work hard. Doing it without the consulting help wouldn’t be possible – it takes too long. We couldn’t have gotten there without the Roadrunner software.