Your 3-minute manufacturing performance newsletter

Expert advice and practical resources

for a more efficient, profitable manufacturing operation

Subscribe to get Throughput straight to your inbox each month:

READ PREVIOUS ISSUES OF THROUGHPUT 📈

How to Make Manufacturing Strong Again

We break down the key reasons why manufacturers struggle to improve productivity and profitability, and how to turn it around.

4 reasons ERPs fail to achieve business goals

ERP investments are soaring, but most still fail to deliver the desired benefits. We explain 4 reasons why your ERP is missing the mark.

New inventory management approach improves bottom-line results

It’s easy for manufacturers to get stuck making incremental improvements. Here’s how Stalmax made the leap to impressive results in just 10 months.

Stop the chaos: How inventory buffers lower costs, increase profit

How can manufacturers become more efficient and profitable in these chaotic, uncertain times? Start by taming the biggest source of chaos: external variability.

25 years of manufacturing performance innovation with TOC

2025 marks our 25th anniversary! Read about our journey, and how we’ve helped 200+ manufacturers up their game using Theory of Constraints methods since 2000.

6 questions to evaluate a tech investment

Consider these 6 questions from Theory of Constraints to evaluate your next tech purchase.

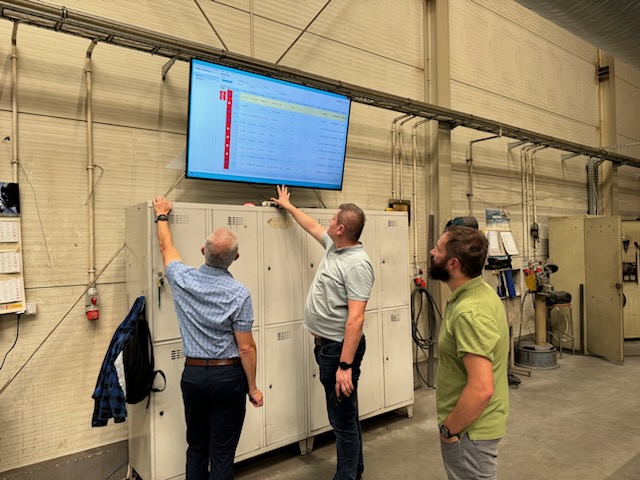

The power of flow

Montera’s Flow Management System helps manufacturers increase ‘flow’ for more revenue and profitability.

CCPM for faster, lower-cost projects

Critical Chain Project Management (CCPM) is a Theory of Constraints approach to deliver projects better, faster and for lower cost.

Tariffs: The Ultimate External Constraint

How to use Throughput Economics tools to manage external constraints (e.g., tariffs) for a profitable path forward.

What constraint is holding your business back?

To find the key constraint holding your operation back, you need to step back and look at the entire business.

About Montera

Your partner for operations and supply chain peak performance

We work with manufacturers worldwide to fix operations and supply

chain problems to increase productivity, revenue and profitability.

Everything we do is based on Theory of Constraints (TOC) and Lean

Thinking for better lead times, forecasting, inventory levels, capacity,

on-time delivery and other KPIs.